Features of Seiki Valve & Spear System

This reliable runnerless molding system enables:

• 100% of the resin to be processed in production

• No secondary process required

• More profits due to faster molding cycles

• Better quality parts

• Automated molding operation, eliminating human factor. (Reliability)

Eliminates problems of conventional hot runner systems. The Spear System has fundamentally solved all technical problems (resin leaking, gate clogging stringing, drooling, burning, gate balance, etc.) that a hot runner system must confront, because the principle is correct.

• Applicable to most thermoplastic resin

• Long service life and maintenance free

• Varieties of models are available, covering part weight from 0.1g through several kg.

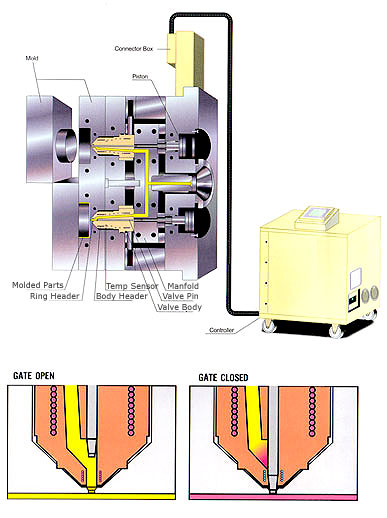

General Construction

The system consists of probes and a manifold that are assembled inside the mold. A controller maintains the temperature of these probes and manifold.

|