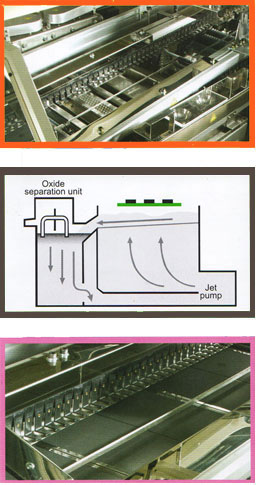

Nozzles Nozzles

The distance between first and second nozzles is around 45mm to provide less temperature drop during dripping.

Primary Nozzle

Designed to suit most of the PCB design to provide a less solder skip of PCB soldering result.

Secondary Nozzle

Designed to provide a high filet and less bridging to PCB design.

OSS(Oxygen Separation System)

The unique mechanism separates solder dross into solder and oxide.

Comparison of oxide yield using OSS:

| |

Without OSS |

With OSS

(30min) |

| M705 after 8hrs

of oxidation |

3.87kg (100%) |

1.93kg

(50.2% reduction) |

| M35 after 8 hrs

of oxidation |

4.03kg (100%) |

2.02kg

(44.9% reduction) |

| Sn-37Pb after

8 hrs of oxidation |

3.32kg (100%) |

1.76kg

(47.0% reduction) |

Solder Pot

The solder pot is heated by strip heaters at both sides and under the solder pot. This made the solder pot easy for maintenance.

Cooling System

The cooling systems are run by fan and air-con cooling systems. Nozzles with adjustable angle to provide best position for the air flowing direction.

Pre-heaters

The pre-heaters surface are made of ceramic which can protect the heater from dirt and flux. It can also prevent fire on the heater.

Inlet and outlet Conveyor

The inlet and outlet conveyors are run by chains(RS-15) which normally use belt. The chain conveyors can withstand the flux.

Finger Cleaning

Cleaning system with horsehair brushes and liquid circulating system (lsopropyl Alcohol). The horsehair brushes do not stick to the solder during cleaning process. |