Underfill Materials for Flip Chips and BGA Applications

Ep Silicone Underfill for Flip Chip Application

< Ep silicone sea island structure > < Ep silicone sea island structure >

Sunstar’s original polymer technology innovated epoxy formulation

for electronics industry. This sea-island structure makes the epoxy

resin flexible and hard to crack. It absorbs stress from thermal

and mechanical shocks. All our UF materials are based on this unique

structure.

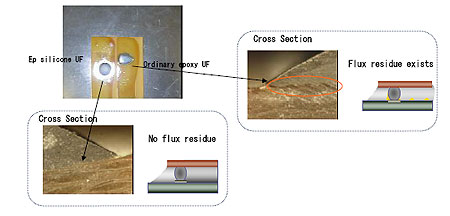

It absorbs flux residue left on a PC

The underfill absorbs flux residue inside and thereby prevents voids from affecting the reliability of underfilled CSP.

<experiment> Apply flux on to FR-4 => heat 3 min. at 220 degrees => apply UF from above

and cures at 150 degrees 30 minutes => cross-section examination

|

| |

|

Reparable Underfill for BGA Application

Characteristics

1. Low temp. snap cure

500μm layer of the material takes only 1 second to gel at over 70 degrees.

2. Excellent reworkability allows for the easy wiping of the resin residue left on PCB.

3. Excellent electrical insulation

4. Excellent storage stability at 5~10C

5. Excellent endurance for mechanical stress(bending stress)

6. Elastic urethane protects solder interconnects from drop shocks.

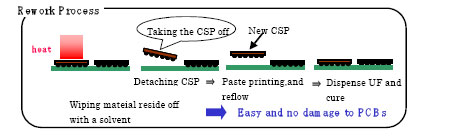

Reworkability

Urethane based underfill, 991 series, eliminates the stressful process of taking the underfilled

CSP off and cleaning the material residue off of the PCB. The underfill chemically dissolves after a heat treatment and allows for an easy wiping of little residue left on the PCB, which makes it possible for engineers to analyze a defect device and also to save expensive PCBs.

|